- Description

- How to Use

- FAQs and Tips

- How to Order

Description:

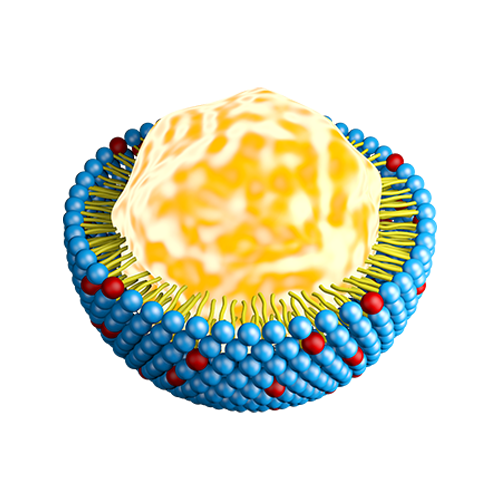

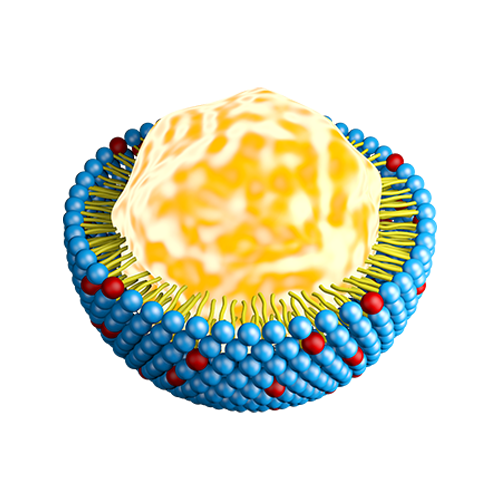

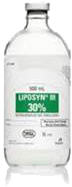

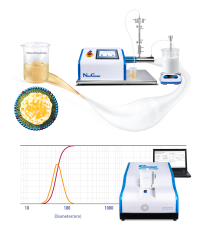

Genizer provides solutions for nanoemulsions, suitable for batch preparation from 25mL to 10L, or continuous manufacturing from 10mL/min to 20L/hour.

While sonication is effective for small-batch nanoemulsions, it is not especially suitable for processing large quantities of certain types of tissues.

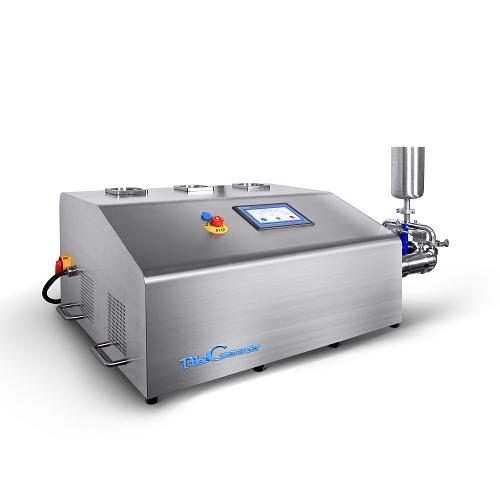

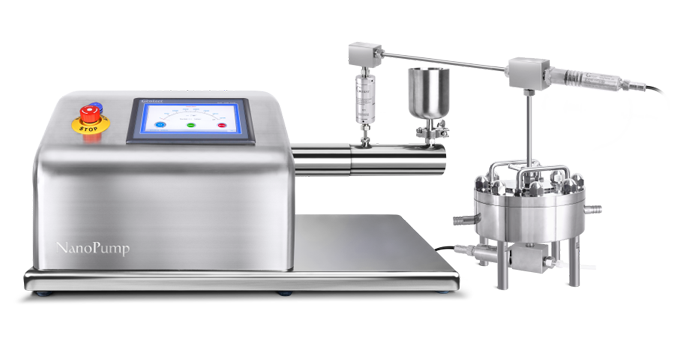

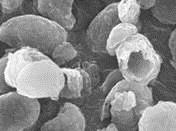

The NanoGenizer, a high-pressure homogenizer, is able to produce nanoemulsions though the combined forces of microfluidization and shear. NanoGenizer maximizes particle reduction, speeds up processing, and lowers the time and overall cost of production.

Not only can high-pressure homogenizers be used for large-batch production of nanoemulsions, they can be set up as part of an inline process, allowing mixing, homogenization, and sterilization of large volumes of nanoemulsions without interruption.

While sonication is effective for small-batch nanoemulsions, it is not especially suitable for processing large quantities of certain types of tissues.

The NanoGenizer, a high-pressure homogenizer, is able to produce nanoemulsions though the combined forces of microfluidization and shear. NanoGenizer maximizes particle reduction, speeds up processing, and lowers the time and overall cost of production.

Not only can high-pressure homogenizers be used for large-batch production of nanoemulsions, they can be set up as part of an inline process, allowing mixing, homogenization, and sterilization of large volumes of nanoemulsions without interruption.

Application:

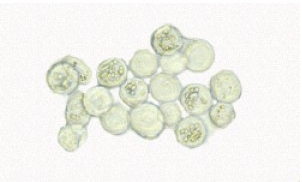

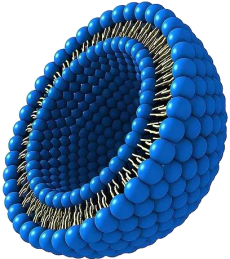

Nanoemulsions provide advantages for extract oil and active ingredients with low bioavailability by:

① Increasing bioavailability and reducing response time, dose and adverse effects.

②Masking the taste of the extract oil.

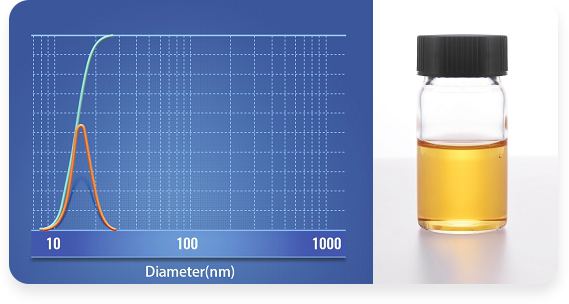

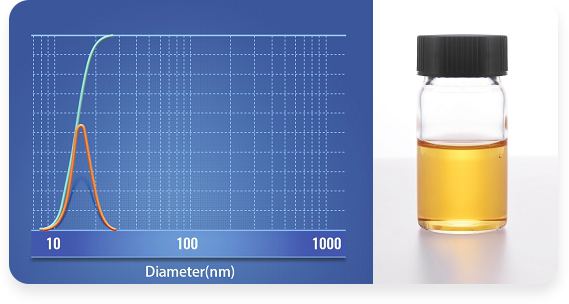

③ Producing translucent droplet sizes of less than 100nm.

① Increasing bioavailability and reducing response time, dose and adverse effects.

②Masking the taste of the extract oil.

③ Producing translucent droplet sizes of less than 100nm.

Performance:

Genizer offers the NanoGenizer high-pressure homogenizer for preparation and online sterile filtering for the sterilization of nanoemulsions without interruption. In addition, Genizer also provides the light scattering particle sizer for measuring the size of nanoemulsions.

High Pressure Homogenizers

| Equipment Name | Capacity | Function |

| NanoGenizer | 20mL-5L | Homogenizing of nanoemulsions |

| NanoGenizer-Dual | 50mL-10L | Homogenizing of nanoemulsions |

| PilotGenizer | 200mL-30L | Homogenizing of nanoemulsions |

| PilotGenizer-Dual | 200mL-50L | Homogenizing of nanoemulsions |

Inline Sterile Filter and Nano Particle Sizer

| Equipment Name | Capacity | Function |

| 47mm Sterile inline filter | 20mL-2L | Sterile filter for the nanoemulsions |

| 90mm Sterile inline filter | 50mL-10L | Sterile filter for the nanoemulsions |

| 142mm Sterile inline filter | 200mL-50L | Sterile filter for the nanoemulsions |

| Nanoparticle sizer Dual | 1nm-10,000nm | Analyzing the size of nanoemulsions |

Recommendation for Nanoemulsions

| Batch | Recommendation |

| 20mL-5L | NanoGenizer; 47mm sterile inline filter; Dual Nanoparticle sizer |

| 20mL-5L | NanoGenizer; 90mm sterile inline filter; Dual Nanoparticle sizer |

| 20mL-10L | NanoGenizer Dual; 90mm sterile inline filter; Dual Nanoparticle sizer |

| 20mL-30L | PilotGenizer; 142mm sterile inline filter; Dual Nanoparticle sizer |

| 20mL-50L | PilotGenizer Dual; 142mm sterile inline filter; Dual Nanoparticle sizer |

| >50L | Please request quote |

USD

USD

949-932-0294 Los Angeles

949-932-0294 Los Angeles  Nano@Genizer.com

Nano@Genizer.com